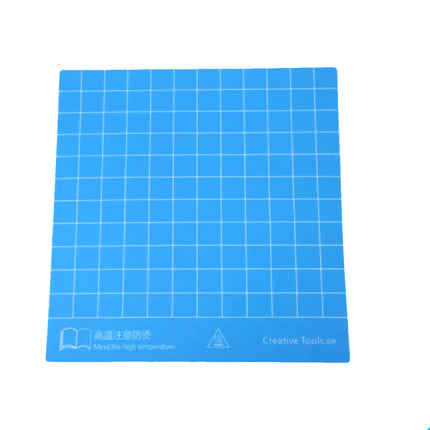

How much will it take for 3D Printer Glass Bed materials?

2020-07-27

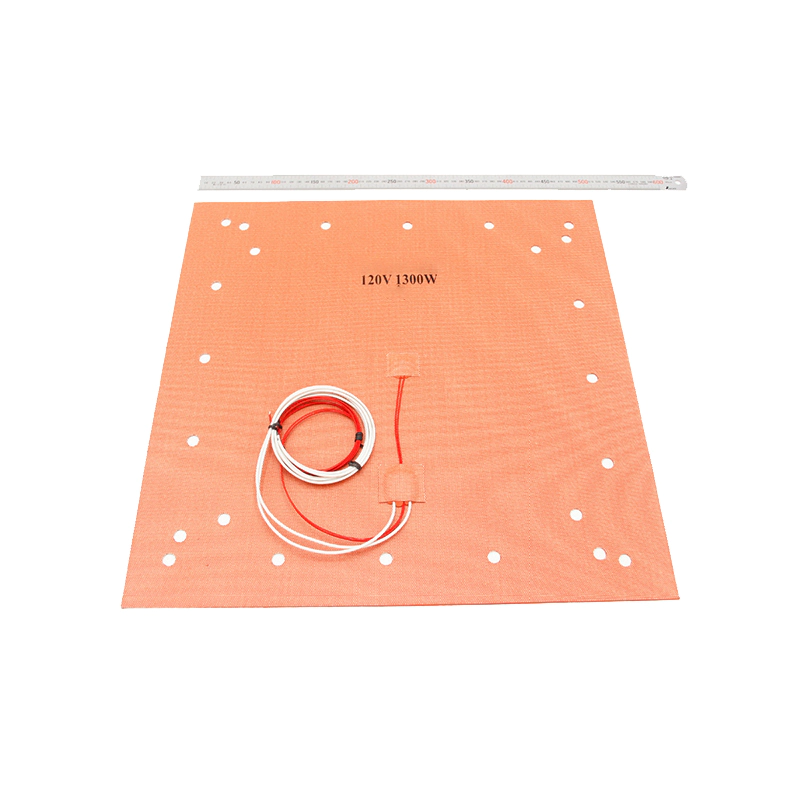

While in the business of producing 3D Printer Glass Bed, the material cost can be one of the biggest expenses, directly affecting profitability. But it is possible to reduce material costs without compromising end product quality and changing customer expectations and dependencies. Like most effective commercial cost reduction measures, reducing commodity costs begins with a comprehensive analysis of the various direct and auxiliary ways in which cash flows from the underlying materials are consumed. Here lists some of the ways Fujian Huansheng Technology Co., Ltd. does to reduce materials cost, to bring benefits to both customers and ourselves: use the lower-cost alternatives if possible, reduce waste, eliminate unnecessary product features, etc.

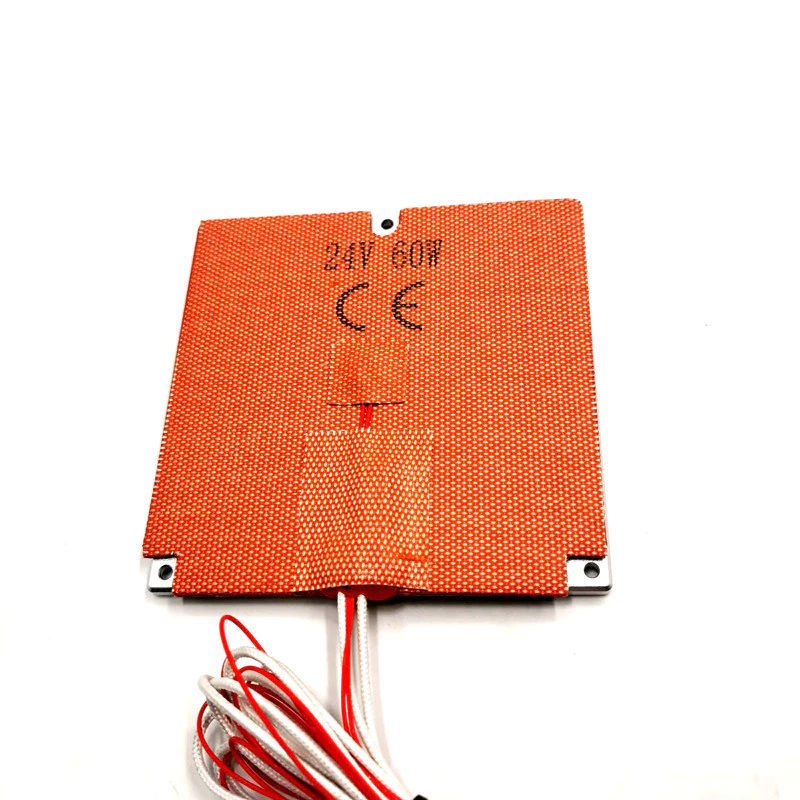

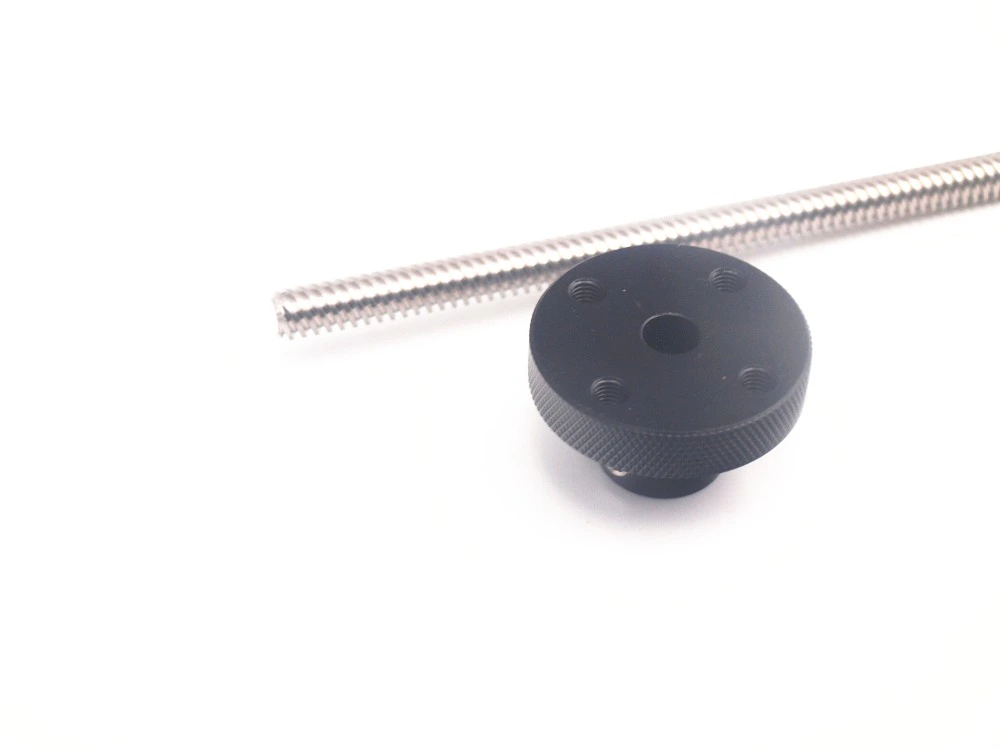

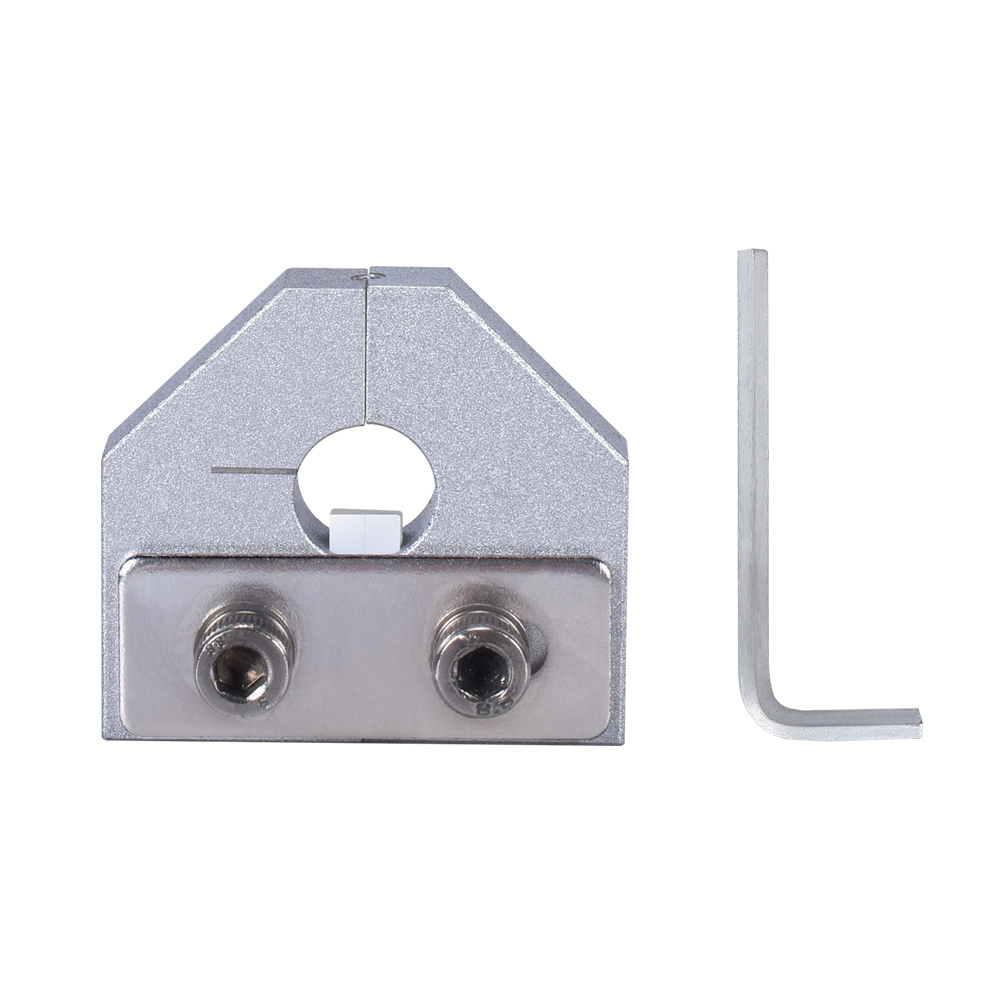

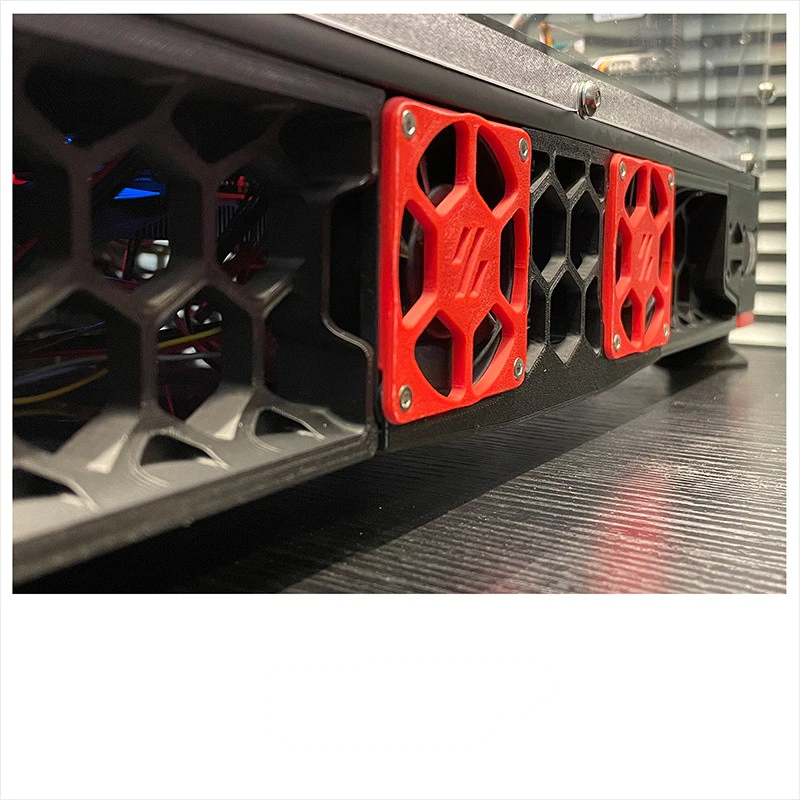

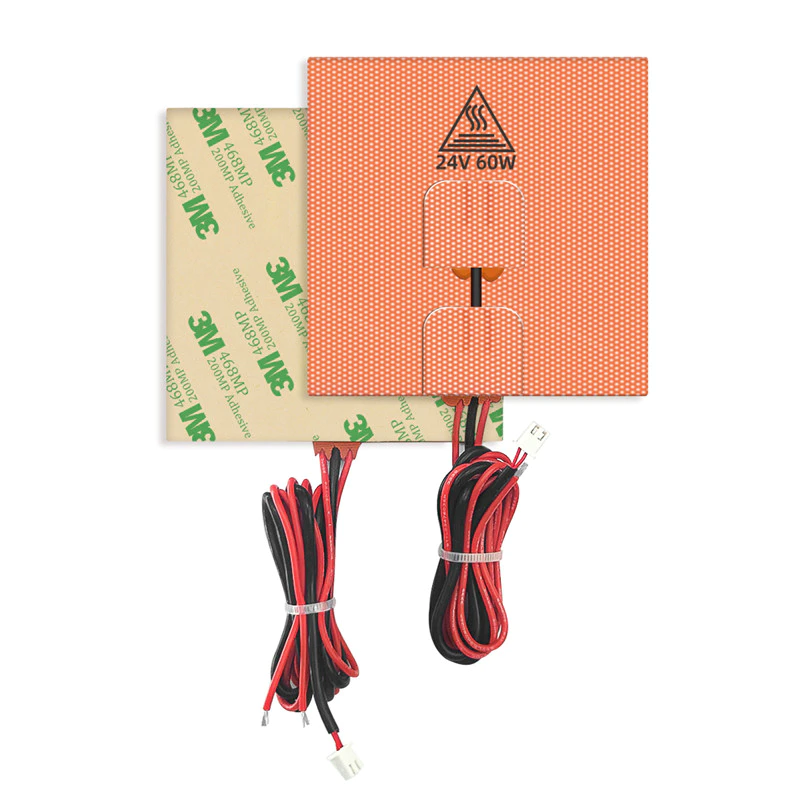

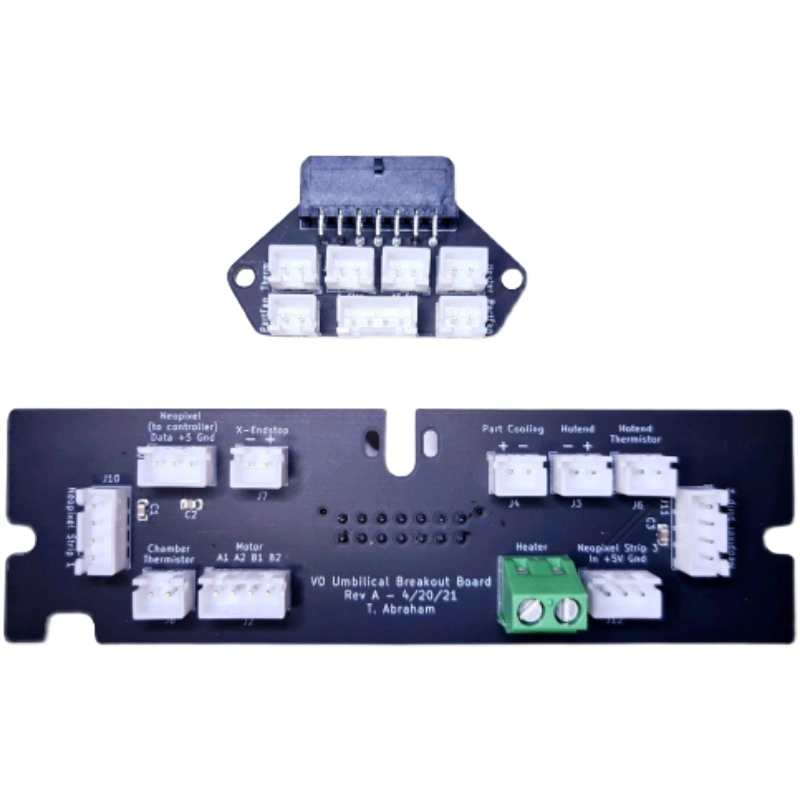

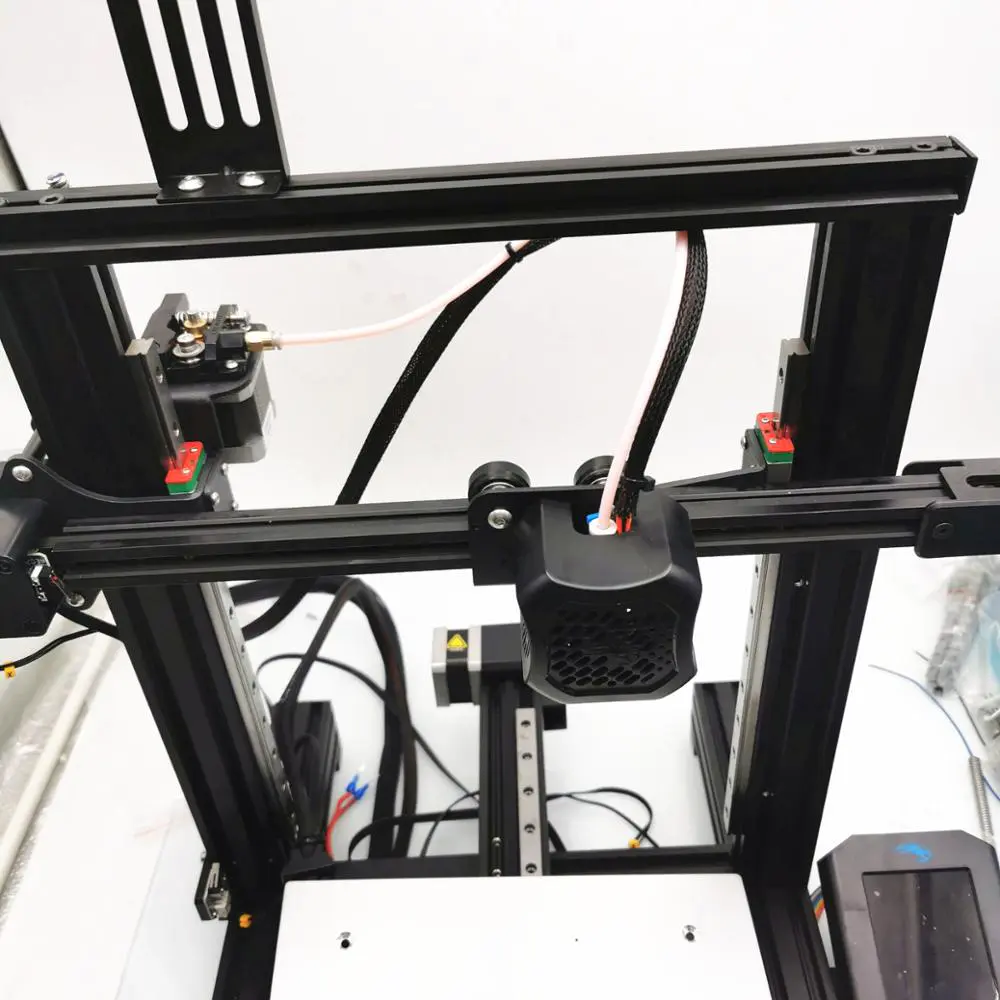

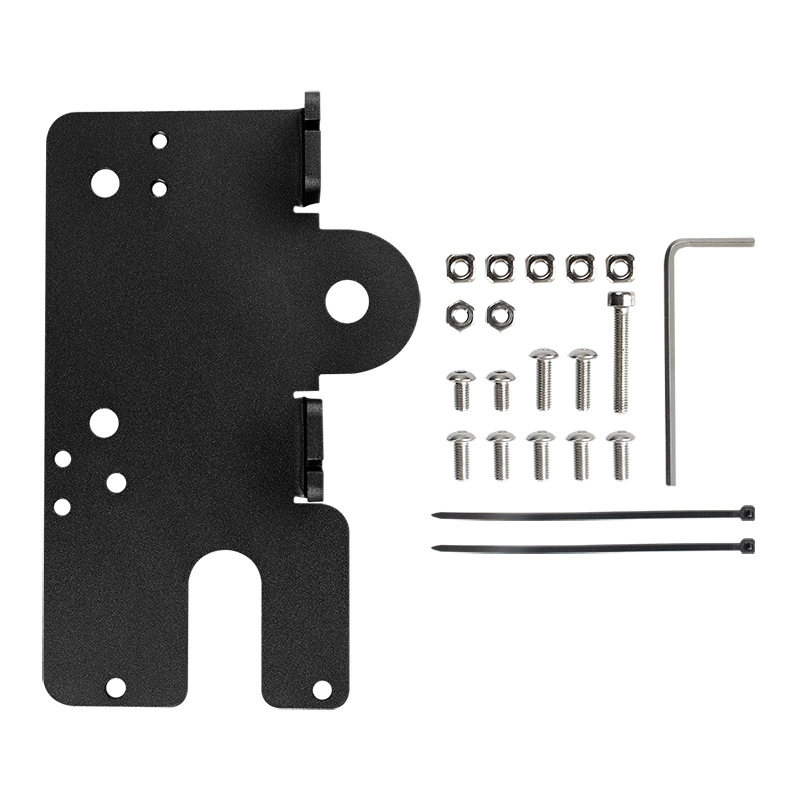

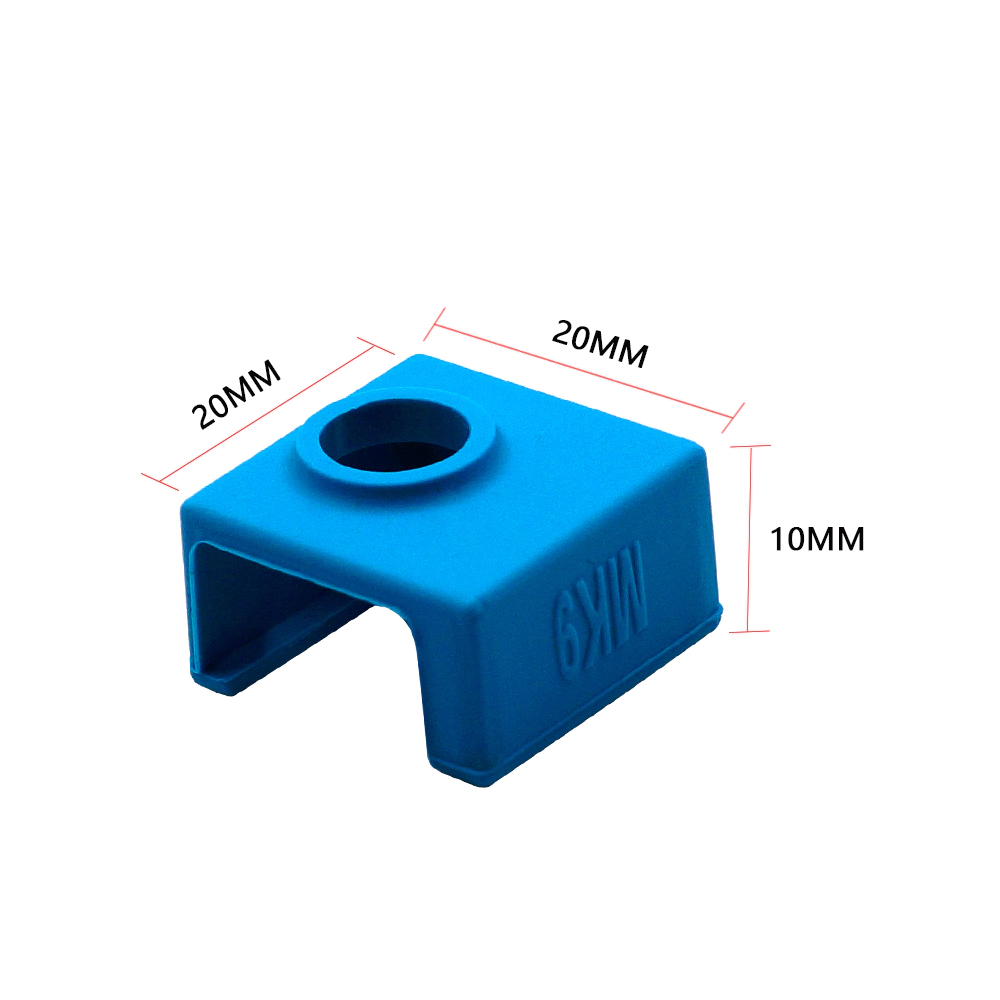

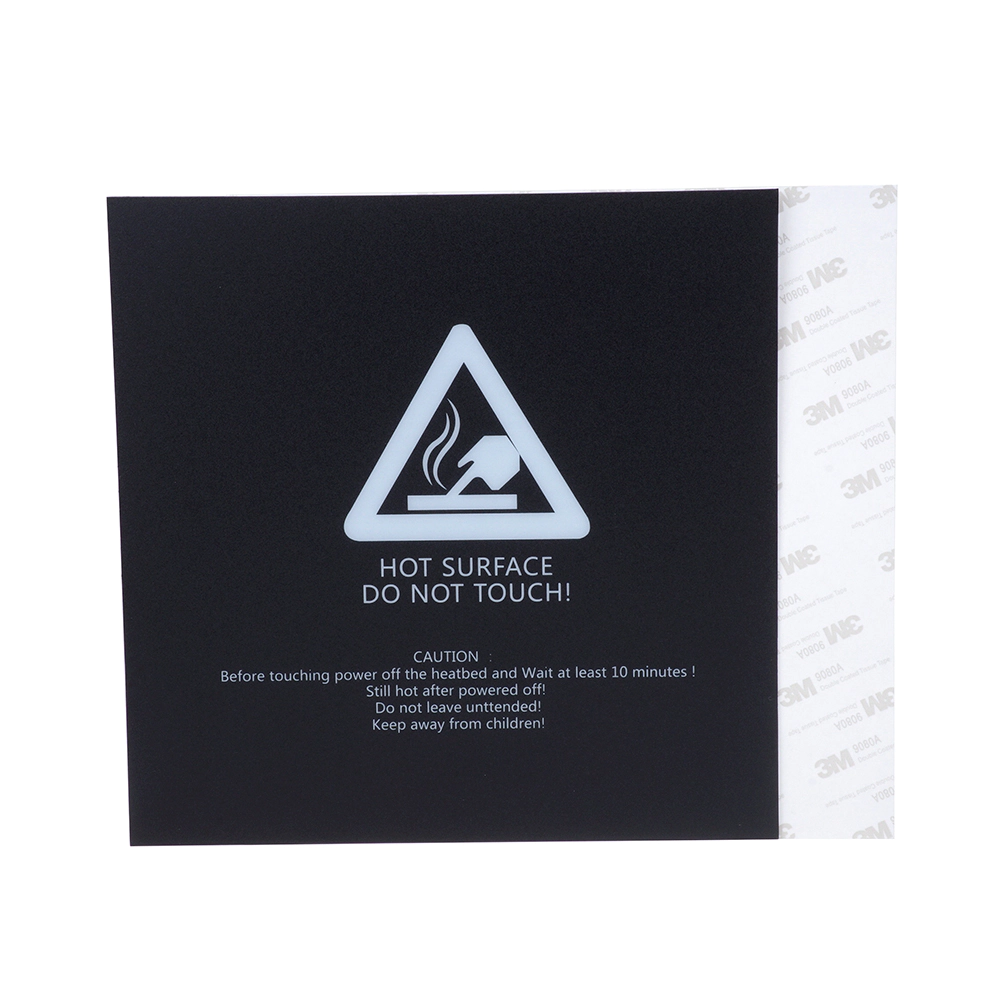

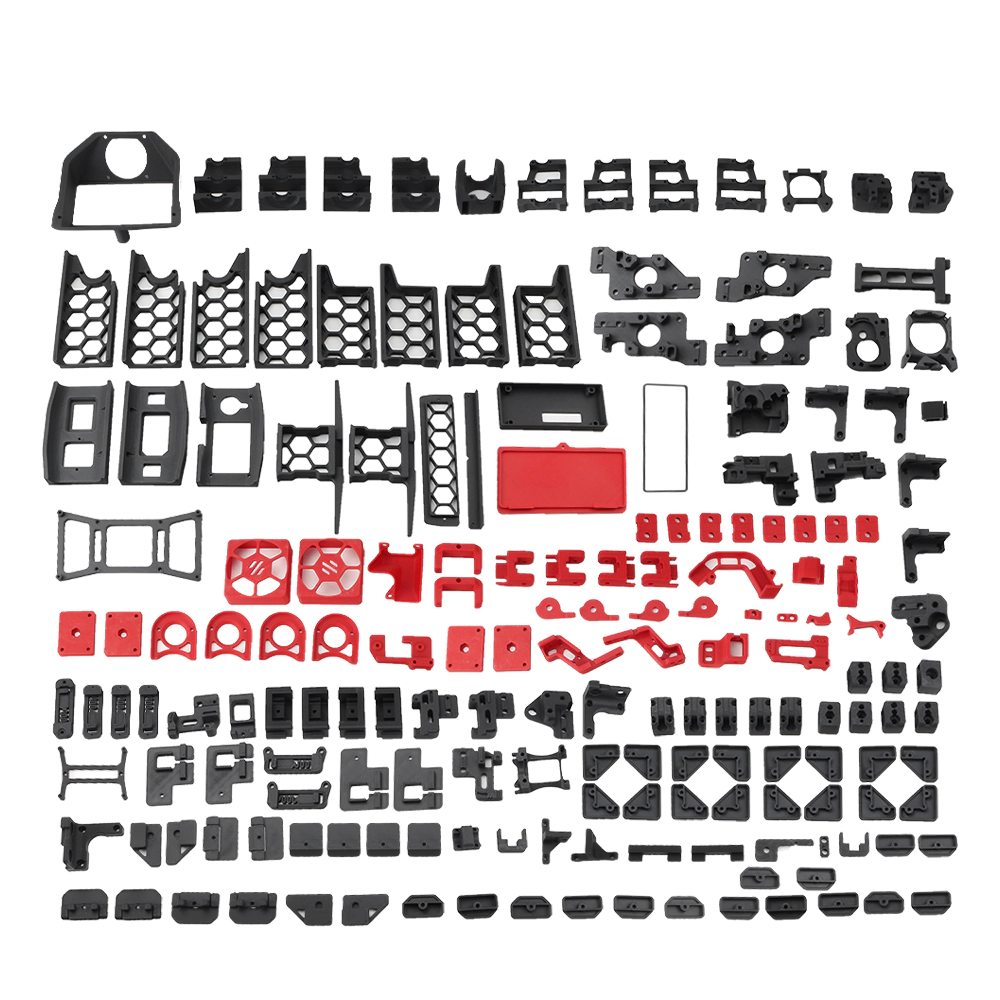

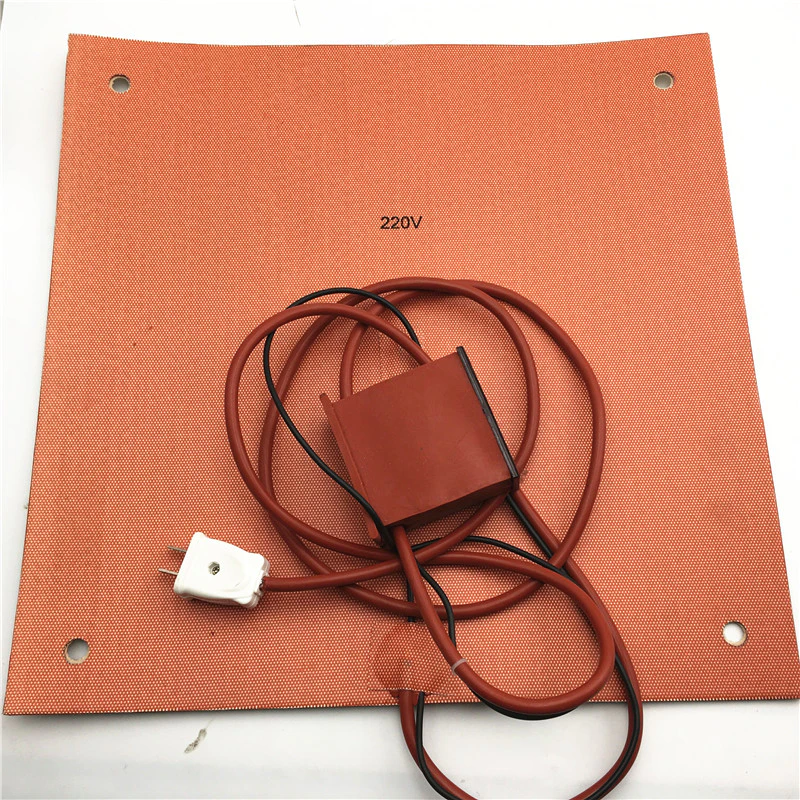

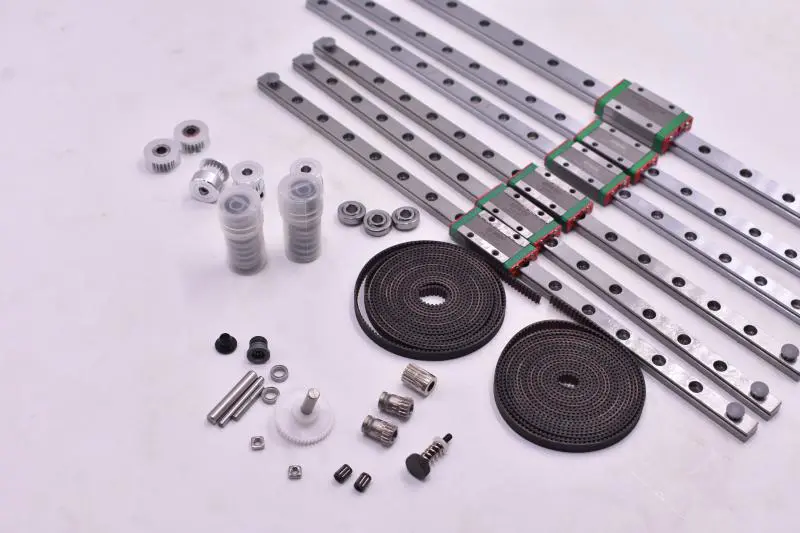

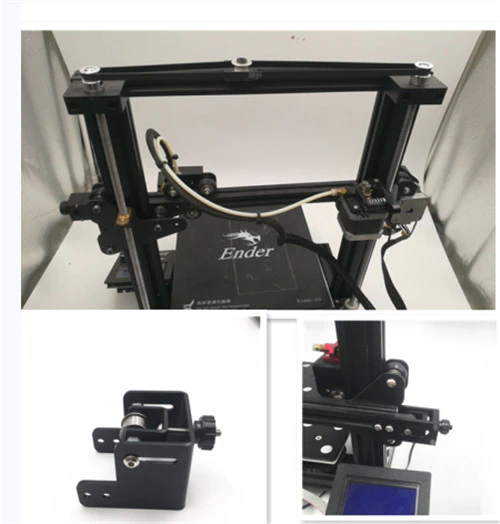

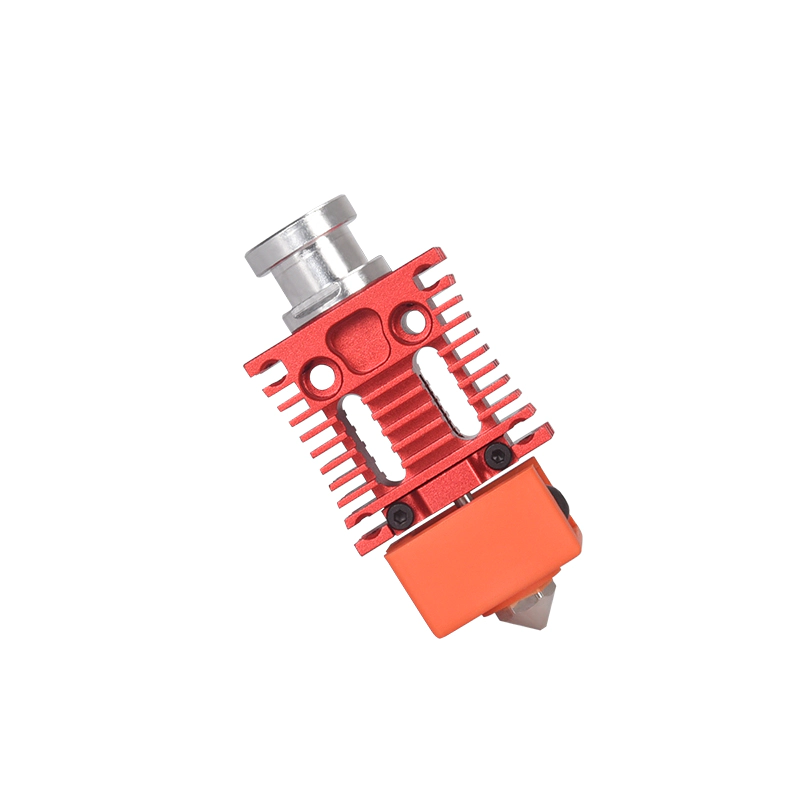

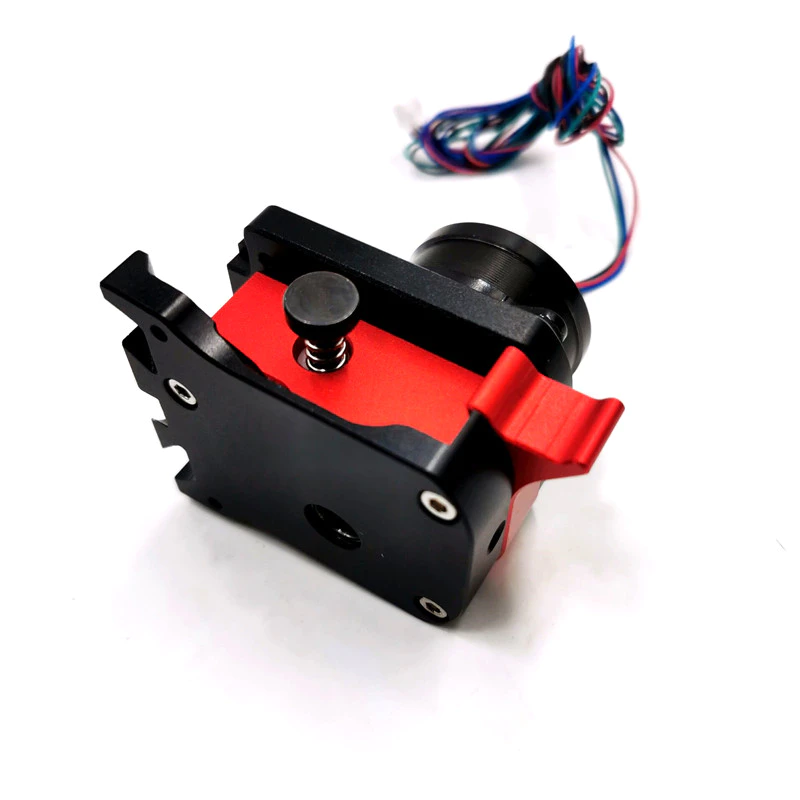

In all aspects of dual extruder 3d printer kit design and production, Funssor has emerged to be the industry leader. Funssor's Nema 17 Damper series are created based on unremitting efforts. During the production of Funssor self-adhesive magnets, its components such as crystalline semiconductor are processed under a very high-temperature environment, so as to ensure its temperature resistance. Product quality is fully compliant with established industry standards.

our company aims to be a globally competitive manufacturer. Get price!

In all aspects of dual extruder 3d printer kit design and production, Funssor has emerged to be the industry leader. Funssor's Nema 17 Damper series are created based on unremitting efforts. During the production of Funssor self-adhesive magnets, its components such as crystalline semiconductor are processed under a very high-temperature environment, so as to ensure its temperature resistance. Product quality is fully compliant with established industry standards.

our company aims to be a globally competitive manufacturer. Get price!

Custom message