Mechanism of a Spinning Wheel

by:Funssor

2020-07-02

The social bookmark creating textile in human endeavor is traditional. Its use in the creation of clothing, floor carpets, blankets and other snack food is extensively in demand for generations primarily because it creates a common group of primary merchandise. Even during the prehistoric period, man had already sought after ways to transform fibers to textile substances. Only a few hundred years ago, man discovered that spinning can twist fibers to form yarn, that are weaved to be able to cloth. This led towards the invention of the our modern world calls 'spinning tyre.'

Spinning wheel is a tool designed make use of the artistic mechanism of spinning in twisting synthetic fiber to create yarn, a mechanism that involves simple functions performed by basic mechanical parts. A spinning wheel is composed primarily of an wheel, explicitly called 'fly wheel' in which responsible for enabling all of the parts to move upon pushing the treadle by foot.

The 'treadle' is this can be the pedal for this spinning wheel and could be likened towards the controls belonging to the vehicle. It requires to be pushed repeatedly to supply mechanical force to the wheel. The turning motion of the treadle is passed with spinning wheel through a connecting tendon called 'footman.' This tendon extends from the tip of the beam attached under the treadle for the base of the spinning rim.

In order for the spinning wheel to drive all other parts, 'drive band' is attached throughout the wheel. This connects to a smaller wheel component called 'flyer whorl.' The purpose of the flyer whorl is receive the mechanical energy from the spinning wheel to turn the 'bobbin,' a cylindrical bar installed horizontally with no flyer whorl and tangential to substantial components for this spinning wheel that stores the spinning fiber.

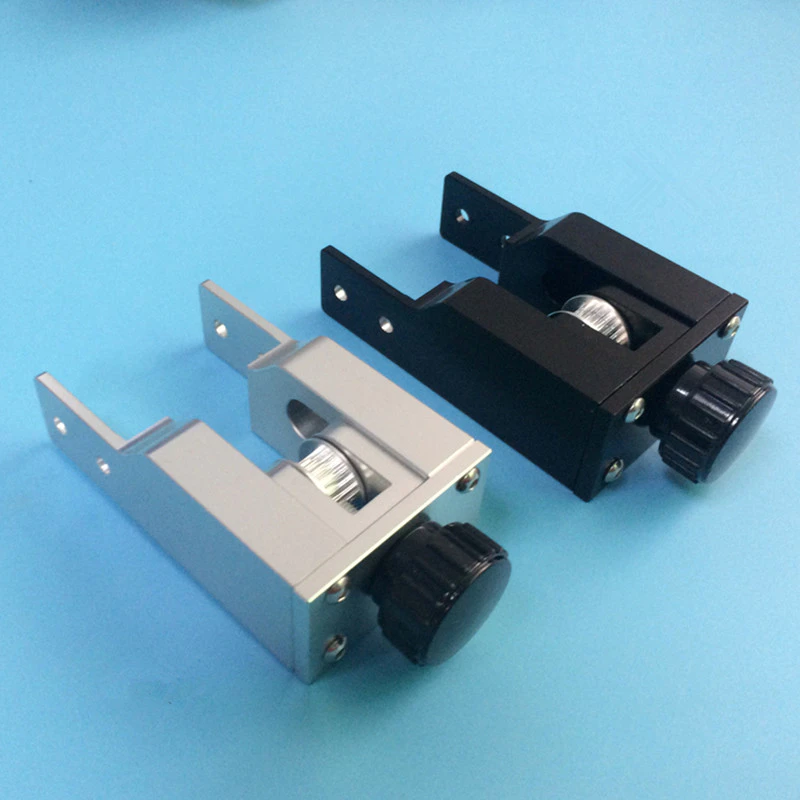

Bobbin is supported by 'flyer,' an U-shape bar attached at one end of the flyer whorl with 2 bars keeping the spinning fibers uniformly collected over the bobbin. The fiber is winched a good opening called 'orifice' that directs it toward the bobbing while guarded by the flyer.

Everything is supported by 'maidens,' two inclined bars founded opposite each other, on a footing known as 'Mother-of-all.' Every one of these parts work with each other to facilitate the performance of the spinning wheel in collecting the fiber and in forming yarn. The efficiency of its performance determines needing spinning supplies in the production of yarn.

Custom message